PU timing belt coatings vary in hardness, surface and heat resistance. Processing as required, suitable for food and heavy industry. Optimize performance…

PU timing belt coating is designed to increase durability, improve friction and meet many specific operating conditions. PU materials can be customized in terms of hardness, thickness and surface structure, ensuring compliance with both the exacting requirements of food processing and heavy industrial loads. Supports machining to size, gluing and creating grooves according to actual requirements.

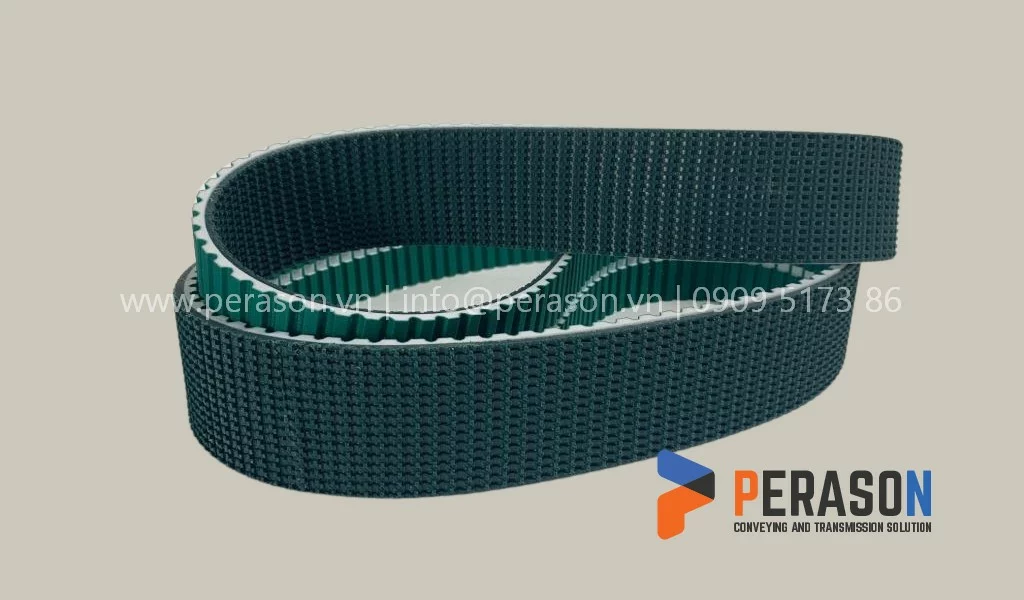

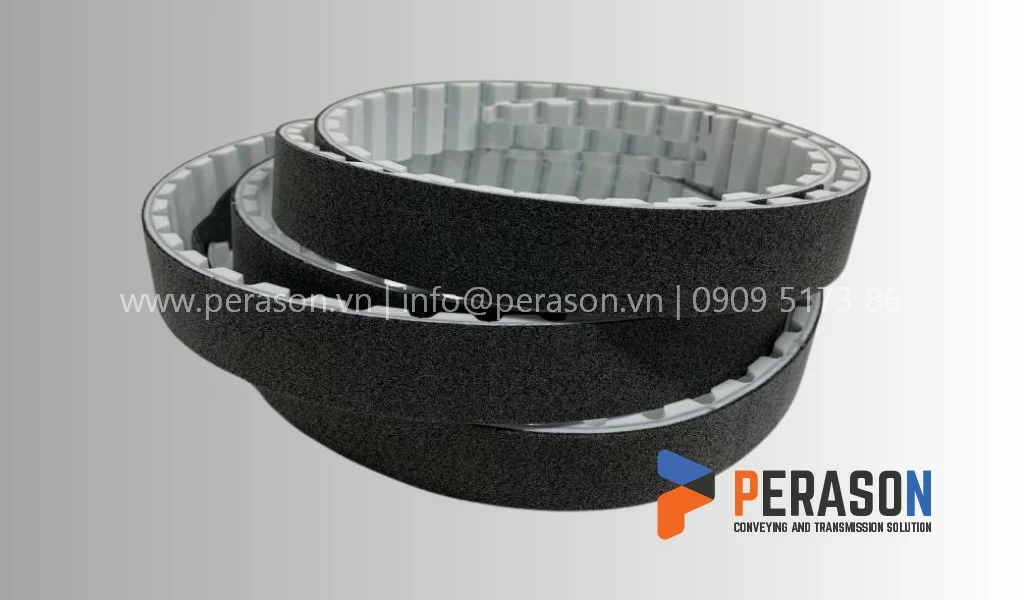

See below a summary table of coating types and images of PU timing belt coating surfaces

Perason offers a full line of coatings for PU (polyurethane) toothed belts, which increase durability, improve load-carrying capacity and expand the belt’s application range in a variety of operating environments. Depending on the type of coating, belts can change their friction properties, abrasion resistance, surface hardness as well as heat, chemical or grease resistance.

PU belt coatings are produced with many levels of hardness and diverse surface structures: smooth surface, textured surface or grooved surface. Each type is designed to suit a specific transport task. Common hardness ranges from 35° Shore A to 75° Shore A, allowing flexible selection according to technical requirements. If you need support, our technical team is always ready to advise on the optimal solution for your actual application.

PU-coated toothed belts are widely used from the food industry, where hygiene and friction control are priorities, to heavy industrial fields, where high load-bearing capacity and mechanical durability are needed, we always have a suitable line of belts. Each application can select the optimal coating to achieve the desired coefficient of friction, wear resistance and thickness.

All coatings and substrates can be customized to customer specifications.

Material table of PU timing belt coatings

| # | Name type coating | Material | Thickness (mm) | Hardness (Shore A) |

|---|---|---|---|---|

| 1 | Chrome leather | natural leather | 3 | 85 |

| 2 | Novo felt | polyester fibre | 1.5 / 2.5 | n.a |

| 3 | Polyamide fabric | polyamide | 0.5 | n.a |

| 4 | Celloflex | polyurethane | 2 - 10 | 20 |

| 5 | Sylomer - G | polyurethane foam | 6 - 12 | 10 |

| 6 | Sylomer - R | polyurethane foam | 6 - 12 | 15 |

| 7 | Sylomer - L | polyurethane foam | 6 - 12 | 15 |

| 8 | Sylomer - M | polyurethane foam | 6 - 12 | 20 |

| 9 | Sylomer - P | polyurethane foam | 12 | 25 |

| 10 | PU foil 85º Sh. A | polyurethane | 1 - 4 | 85 |

| 11 | PU foil 60º Sh. A | polyurethane | 2 | 60 |

| 12 | PU longitudinal groove | polyurethane | 2 | 60 |

| 13 | PU yellow | polyurethane | 2 - 10 | 55 |

| 14 | PU grey | polyurethane | 2 - 3 | 55 |

| 15 | Polythan | polyurethane | 2 - 5 | 70 |

| 16 | PVC blue | polyvinyl chloride | 1 - 3 | 40 |

| 17 | PVC white | polyvinyl chloride | 1.5 | 65 |

| 18 | PVC knobs white | polyvinyl chloride | 1.8 | 65 |

| 19 | PVC Fishbone white | polyvinyl chloride | 3 | 65 |

| 20 | PVC Saw tooth profile | polyvinyl chloride | 3 | 65 |

| 21 | Supergrip green | polyvinyl chloride | 3.5 | 40 |

| 22 | Supergrip white | polyvinyl chloride | 3.5 | 50 |

| 23 | Supergrip petrol | polyvinyl chloride | 3.5 | 40 |

| 24 | Supergrip black | rubber | 3.5 | 70 |

| 25 | Porol | rubber | 2 - 15 | RD165 |

| 26 | EPDM rubber | rubber | 2 - 10 | 70 |

| 27 | Rubber white | rubber | 2 - 10 | 50 |

| 28 | Correx | natural rubber | 4 - 10 | 40 |

| 29 | Linatex | natural rubber | 1.6 - 12 | 40 |

| 30 | Linatrile | Polymer - NBR | 2.4 - 5 | 50 |

| 31 | Elastomer green | rubber | 1 - 2 | 60 |

| 32 | Rubber sponge | rubber | 10 - 15 | RD250 |

| 33 | Teflon | teflon | 0.3 | n.a |

| 34 | Magnetic foil | rubber ferrit | 1 | n.a |

| 35 | RP400 | rubber | 2 - 6 | 38 |

| 36 | Viton | rubber | 3 - 5 | 75 |

| 37 | G/GSTR | rubber | 0.5 - 12 | 60 |

| 38 | Silicone | silicone | 0.5 - 12 | 40 |

| 39 | Brex-red | polyurethane | 2 | 60 |

| 40 | Bbex-blue | polyurethane | 2 | 60 |

Image of PU timing belt coating surface

In addition, choosing the right coating material requires specialized hardness measuring equipment and a thorough understanding of the application to select the appropriate replacement belt. Perason has experience providing coated belts. If you need it, please contact us for consulting support and the most competitive quote.