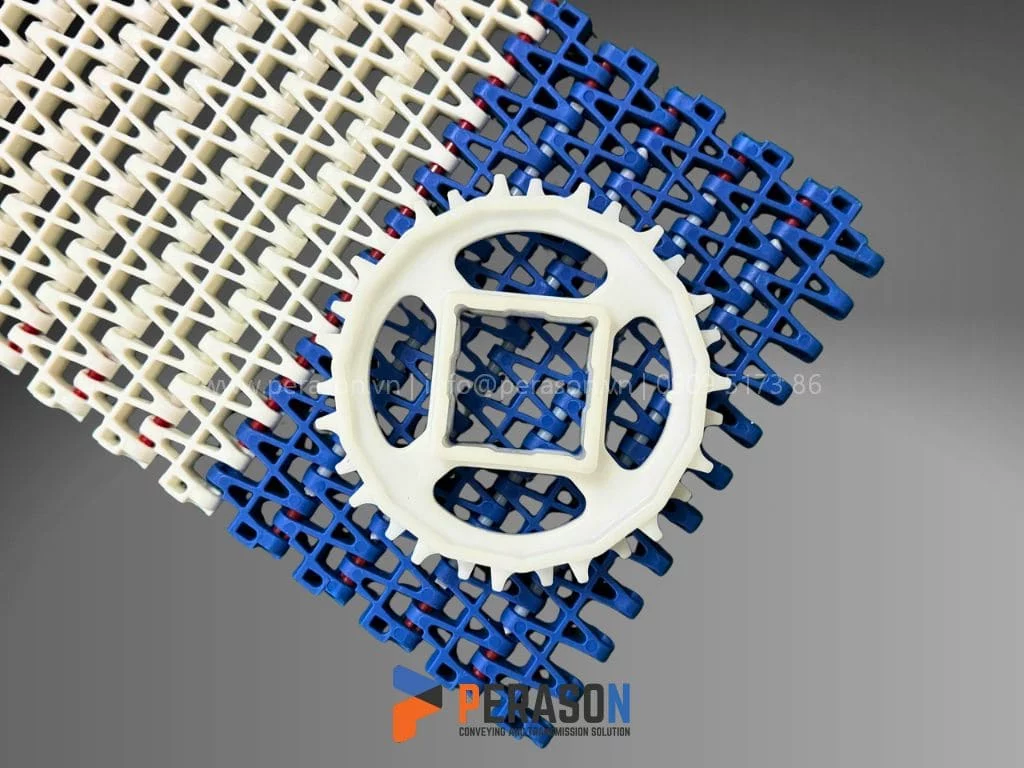

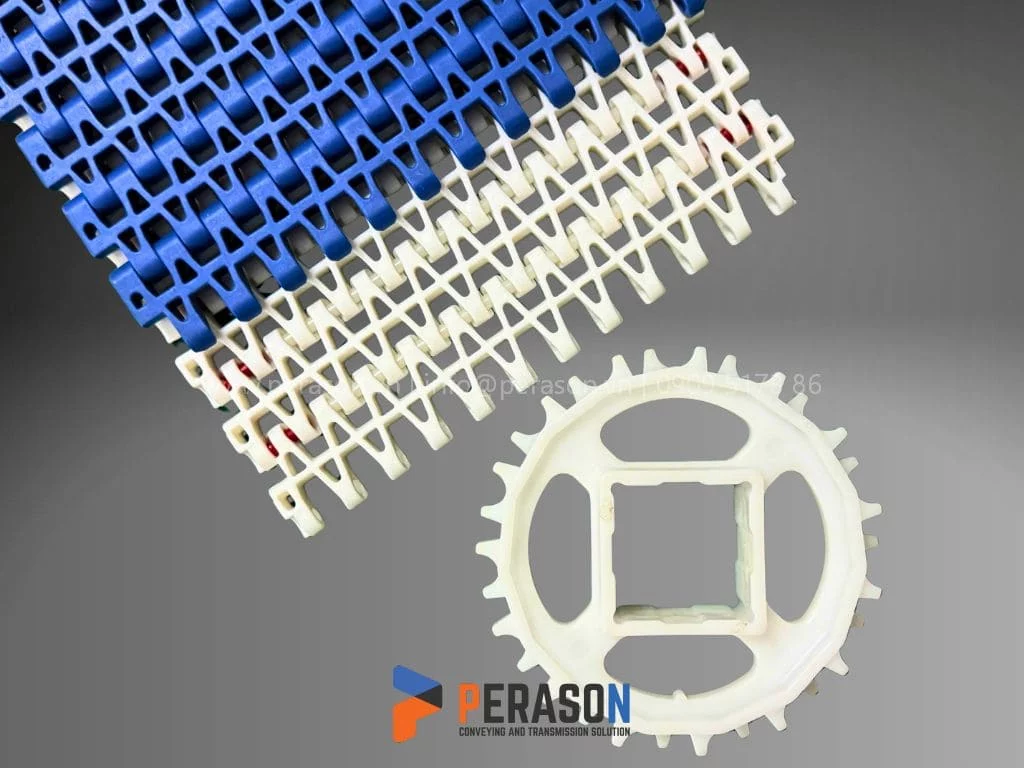

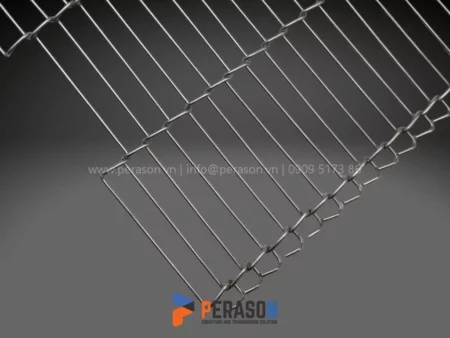

HS-2500B HongsBelt General introduction about conveyor widely used in drying, washing, and cooling applications

Hongsbelts HS-2500B is one of the most prominent and popular modular plastic belt conveyor products of the Hongsbelts brand (China). This product is designed as a cost-effective, high-quality solution with high compatibility with 1-inch Flush Grid conveyor belts from leading global brands (such as Habasit M2533 or Intralox Series 900).

Key Features of HS-2500B

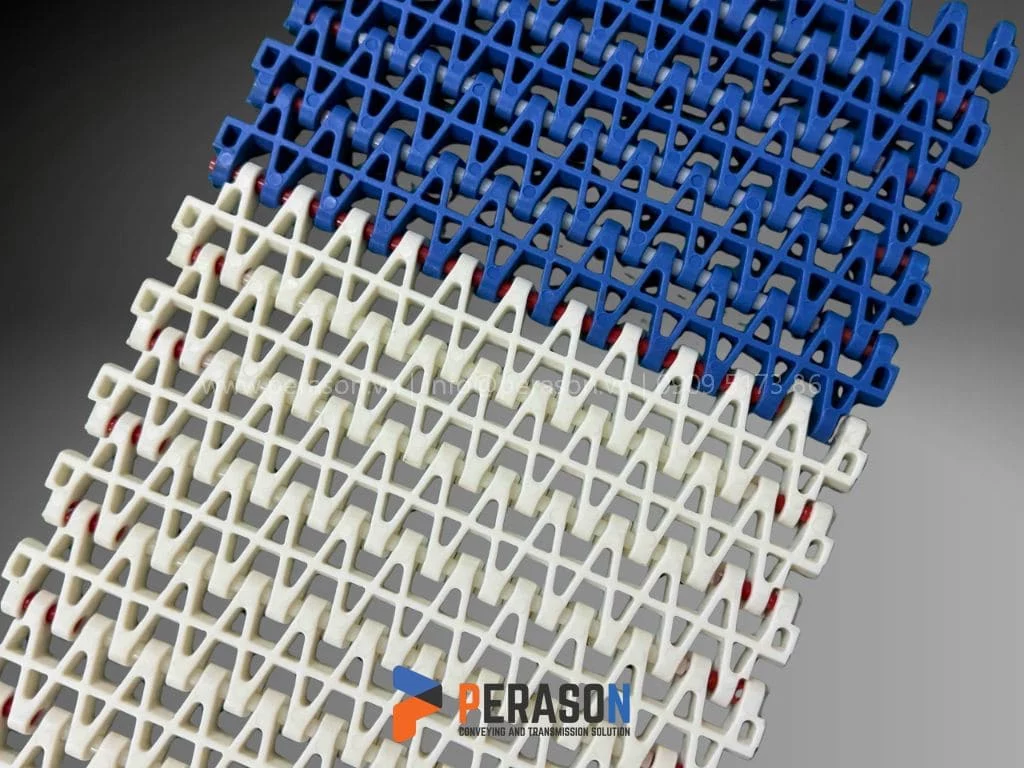

Open Grid (Flush Grid) Design:

- HS-2500B features an open grid surface, allowing water, air, or chemicals to easily pass through the conveyor.

- Ideal Applications: Production lines that require drainage, product washing (vegetables, seafood), cooling, drying, or ventilation.

- Surface Open Area: Approximately 31.7%.

Chain Pitch 1-inch (25.4 mm):

- This is the most common standard chain pitch used in many industries, especially in food and beverage processing.

- Compatibility: The 1-inch design allows HS-2500B to easily integrate with or replace conveyor lines with the same chain pitch without modifying the sprocket system or drive structure.

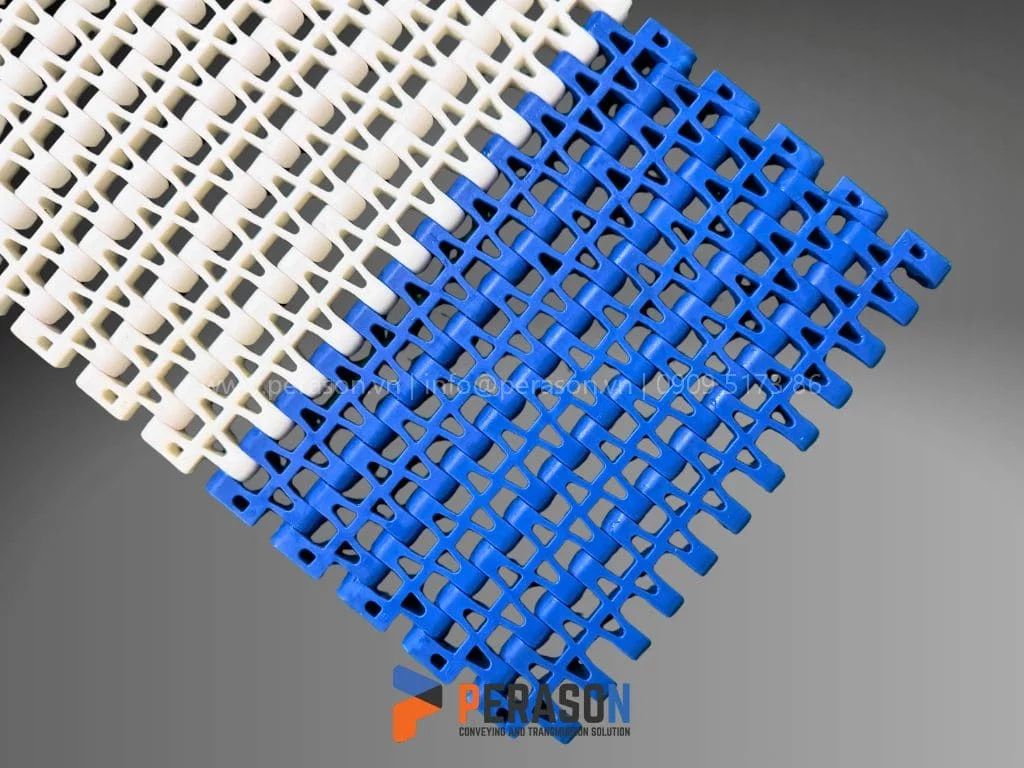

Material Options:

HS-2500B is manufactured from various engineering plastics to meet different environmental requirements:

- POM (Acetal): High mechanical strength, good wear resistance, capable of bearing heavy loads, suitable for cold environments (freezing).

- PP (Polypropylene): Chemical resistant, good acid/alkali resistance, suitable for washing environments.

- PE (Polyethylene): Withstands extremely low temperatures, ideal for deep-freeze applications.

| Modular belt specifications | Technical details |

|---|---|

| Type | HS-2500B |

| Pitch | 25.4 mm |

| Thickness | 10 mm |

| Open area | 31.7% |

| Rod diameter | 4.9 mm |

| Type driven | Run straight |

Typical Applications

- Food Processing: Cooling bread, drying products, transporting fruits and vegetables after washing.

- Seafood: Washing lines, sorting, freezing shrimp and fish.

- Packaging: Transporting containers and plastic trays that require drainage.

- General Industry: Conveying and storing applications where surface openness is needed.

In summary, the Hongsbelts HS-2500B is the optimal choice for businesses seeking a reliable 1-inch open mesh conveyor belt that meets hygiene standards and is particularly a cost-effective solution for maintenance and replacement of components.

In addition, this type of conveyor is fully compatible and can replace the Habasit M2533 conveyor that you are currently using. Detailed specifications are quickly compared by Perason below to help you better understand these two types of plastic conveyors.

Detailed comparison between Hongsbelts HS 2500B and Habasit M2533

These are two directly competing products designed to be interchangeable in terms of functionality. Both are plastic modular belts with a flush grid surface and a 1-inch (25.4 mm) pitch, making them suitable for the same applications and, in many cases, compatible with the same type of sprocket.

The main differences lie in brand positioning, specific modular design, and cost. Habasit is a global premium brand, while Hongsbelts is a major competitor often positioned as a high-quality alternative at a cost-effective price.

| Conveyor belt feature | Habasit M2533 | Hongsbelts HS 2500B |

|---|---|---|

| Product type | HabasitLINK® | Hongsbelts HS 2500 Series |

| Pitch | 1" (25.4 mm) | 1" (25.4 mm) |

| Surface type | Flush Grid | Flush Grid |

| Thickness | 10 mm | 10 mm |

| Open area | 35% | 31.7% |

| Rod diameter | 5 mm | 4.9 mm |

| Hinge design | Open Hinge | Open Hinge |

| Material | POM (Acetal), PP (Polypropylene), PE (Polyethylene) | POM, PP, PE, PA (Nylon) |

| Popular applications | Cooling, draining, washing, drying, normal transportation | Cooling, draining, washing, drying, normal transportation |

Analysis of “Compatibility” and Key Differences

Brand & Cost:

Habasit (M2533): A leading brand based in Switzerland, known for high-performance engineering and a global service network. This often comes with a premium price.

Hongsbelts (HS 2500B): A major Chinese manufacturer that has developed into a significant global competitor. Their products are often marketed as a “perfect replacement” or “interchangeable” with premium brands like Habasit and Intralox, offering equivalent quality at a more competitive price.

Design & Performance Statements:

Habasit M2533: The main selling point of Habasit is its proprietary modular design. They claim that the M2533 has “softer edges” and a superior surface that better supports products, which is crucial for soft or easily marked items (such as pastries or soft-skinned fruits). They assert that this design helps reduce product damage and waste.

Hongsbelts HS 2500B: Hongsbelts focuses on durability, long service life, and ease of maintenance. Their core value emphasizes providing a robust, reliable, and economical solution that meets industrial standards.

Sanitary Design (Food Safety):

Habasit M2533: Habasit strongly promotes the superior cleanability of its open hinge design, claiming it has a higher rod exposure (up to 26% compared to some competitors). This makes the hinges—a key area for bacterial growth—easier to access for cleaning and sanitation, which is a critical factor in food processing.

Hongsbelts HS 2500B: The HS 2500B also uses a standard open hinge design, suitable for food-grade and sanitary applications, but it is generally not marketed with claims of proprietary hygienic design, specifically like Habasit conveyors.Surface Open Area:Habasit M2533 has a slightly larger surface open area (35% versus 31.7%). This small difference could be a factor in applications requiring maximum airflow or drainage, giving a slight advantage to the M2533.

Which one should you choose?

Choose Habasit M2533 if:

- Your budget is flexible and you prioritize the latest hygiene and food safety design above all.

- You are transporting a very delicate or soft product (such as unbaked dough or soft-skinned fruit), where the proprietary ‘soft edge’ surface can significantly minimize waste.

- Your facility has standardized on Habasit products and you value support and service from a single premium supplier.

Choose Hongsbelts HS 2500B if:

- Cost is the primary deciding factor. You can get a conveyor with equivalent functionality at a significantly lower price.

- You are looking for a reliable ‘workhorse’ conveyor for a standard application (e.g., cooling baked goods, draining washed vegetables, transporting packaged goods).

- You need a direct drop-in replacement for an existing 1-inch open mesh conveyor (including Habasit or Intralox) and want a more economical option for maintenance and replacement.

In summary, between HS2500B and M2533

The difference between these two conveyor lines does not lie in the basic numbers, but in design philosophy and brand positioning.

1. Advantages in Design and Hygiene (Habasit M2533)

- Habasit, as a pioneering brand, focuses on optimizing operational performance and hygiene standards:

- Optimized product surface: Habasit promotes its proprietary module design with “soft edges” and a smoother contact surface. The benefit is minimizing the risk of damage, marking, or deforming delicate products (such as pastries, cold cuts, soft fruits), thereby significantly reducing waste rates.

- Superior hygiene: The M2533 is designed with an open hinge that has a high pin gap, making the hinge area easier to access for cleaning. In food processing environments, the ability to clean quickly and thoroughly is crucial to prevent bacterial buildup.

- Drainage/Cooling Efficiency: With a larger surface opening (35%), M2533 provides more effective drainage, vapor release, or product cooling in washing or drying tunnel applications.

2. Cost Advantage and Replaceability (Hongsbelts HS 2500B)

Hongsbelts HS 2500B is a strategic choice based on the balance between quality and cost:Competitive pricing:

- This is the biggest advantage. Hongsbelts often offers significantly lower prices compared to Habasit M2533, helping businesses save on initial investment and routine replacement maintenance costs.

- High replaceability: Hongsbelts positions the HS 2500B as a direct replacement for the Habasit M2533. This means that businesses currently using the M2533 conveyor belt can easily switch to the HS 2500B without having to change the sprocket system or conveyor structure.

- Reliable durability: Despite the lower cost, the HS 2500B is still manufactured from standard industrial materials (PP, POM) and promises high durability, suitable for most standard conveying applications.

IMPORTANT: Don’t let choice slow down your workflow!

You are already familiar with the advantages and disadvantages of the Habasit M2533 and Hongsbelts HS 2500B. The next step is to make the decision that best fits your budget, product, and production environment.

Choosing the wrong conveyor belt can lead to higher maintenance costs, reduced equipment lifespan, and increased scrap rates. Let our experts help you eliminate that risk.

Delays are costly. Optimize performance today!

If you need an emergency replacement solution (spare parts) for your current 1-inch Flush Grid conveyor, contact us immediately. We are committed to providing compatible solutions for the Habasit M2533 or Hongsbelts HS 2500B with the fastest delivery time.

Hotline 24/7 support : 0909 5173.86 – Ms. Hang

Email: info.perason.vn