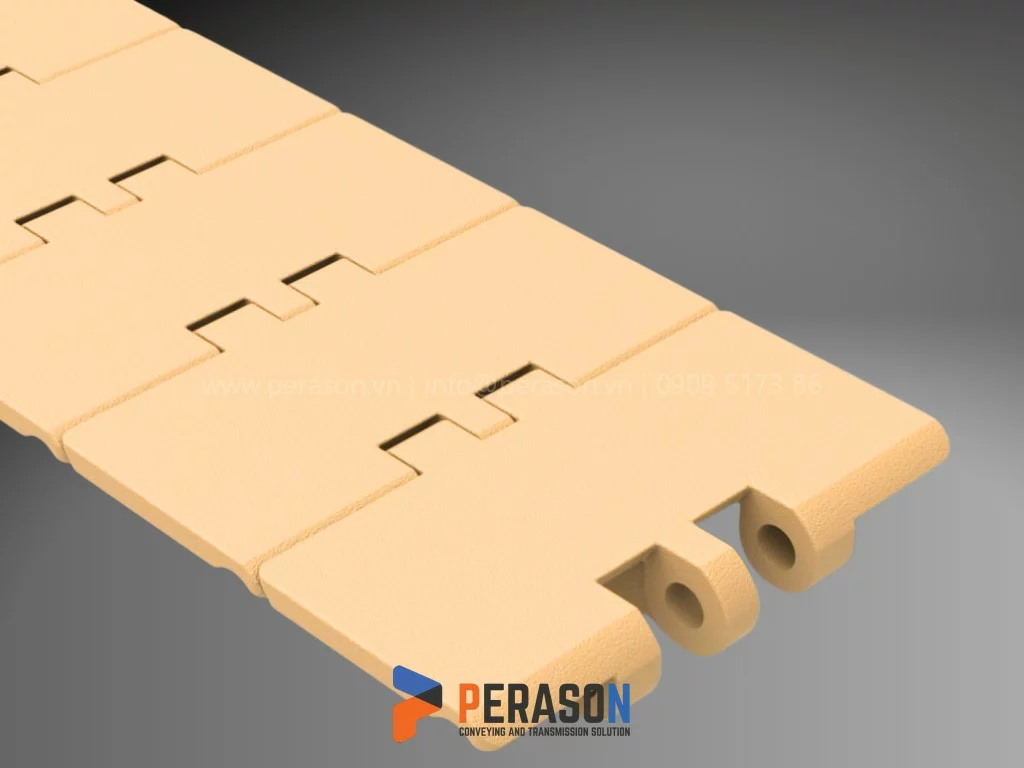

Plastic Flat Top Chain 820 is one of the most common and widely used plastic conveyor chain series globally, especially in industries requiring high standards of hygiene, speed, and stability, such as food processing, beverages, dairy, and bottling/labeling machines. This chain series is a superior replacement for traditional stainless steel chains due to its extremely quiet, durable operation, and minimal noise reduction during continuous operation.

Key Technical Specifications of Flat Top Chain 820

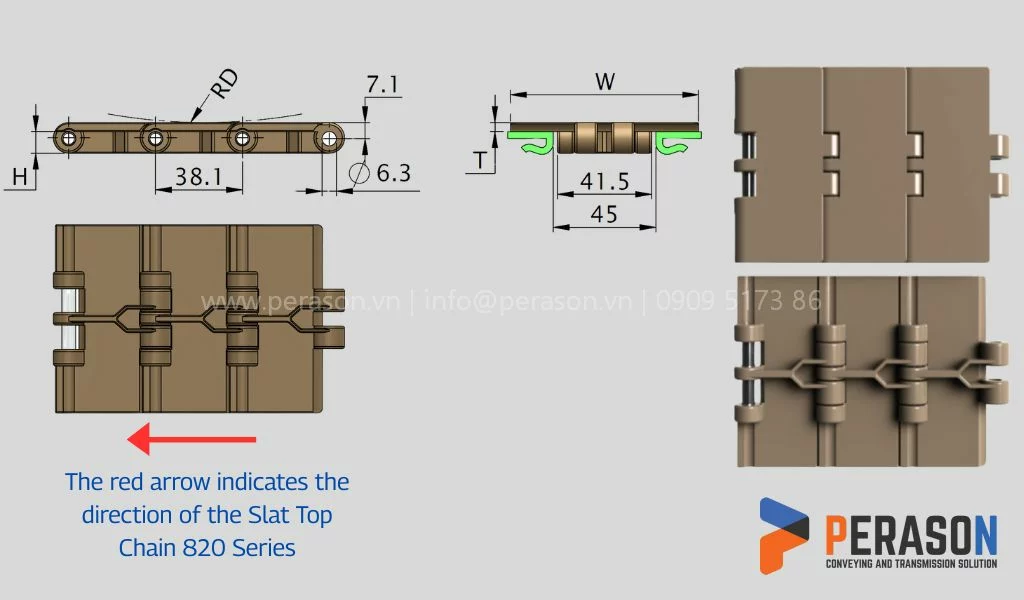

Understanding the technical specifications is key to selecting and designing a conveyor chain system for optimal performance.

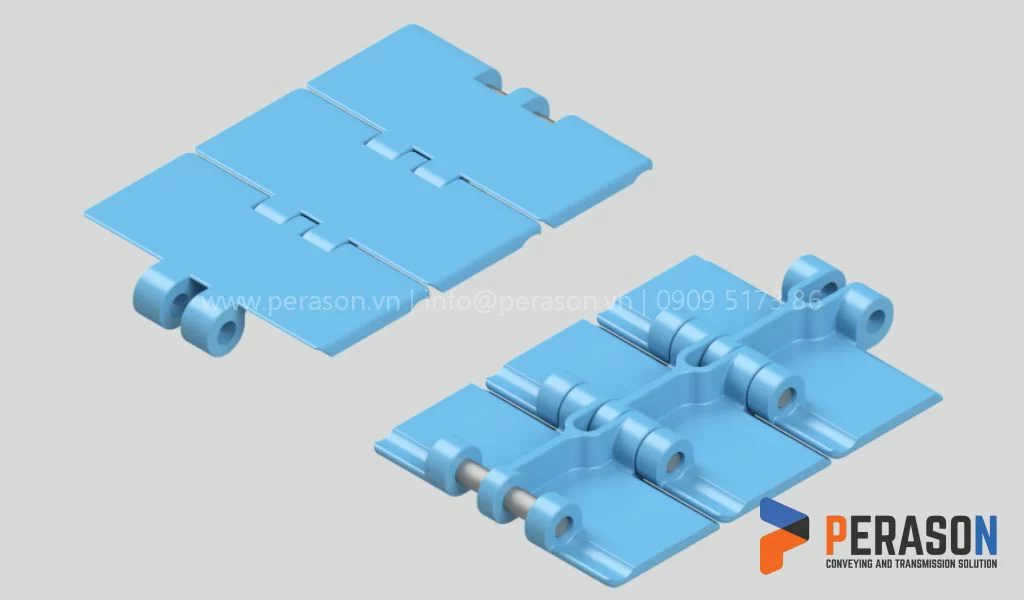

Detailed Structure:

- Chain Plate Material: POM Acetal (LF Brown, AS Black) / PP…

- Color: Brown, white, black, dark blue, orange, green…

- Pin Material: Stainless steel pins 304 and 201 / Plastic pins customized upon request

- Chain Pitch: 38.1 mm (Equivalent to 1.5 inches)

- Allowable Tensile Strength (POM): 2000 N (450 lbf)

- Maximum Operating Speed: 80 m/min (When lubricated) / 50 m/min (When dry running)

- Maximum Designed Conveyor Length: 12 meters (Optimal length, not exceeding 9 meters/line)

- Working Temperature: -40°C to 90°C

- Packaging Specification: Box of 80 links = 3.048 meters (10 feet)

- Minimum Reverse Bending Radius (Top Surface Bending): 75.0 mm (3.00 inches)

Production Applications Using the Flat Top Chain 820 Series

- Beverages: Filling lines, PET bottling, glass bottling, aluminum/steel can packaging. Popular codes: 820-K325 / 820-K450.

- Food Production: Conveying chocolate boxes, biscuit boxes, milk cartons, yogurt cups, chili sauce production, bottled and filled food products using code 820-K600.

- Packaging: Labeling machines, Shrink wrapping machines, capping conveyors. Using codes 821-K450 to K750 (Heavy load/High speed).

- Pharmaceuticals: Conveying medicine bottles, finished medicine boxes. Popular codes: 820-K325-K450.

- Cosmetics (F&B Industry): Conveying shampoo bottles, skincare products. Code: 820-K750.

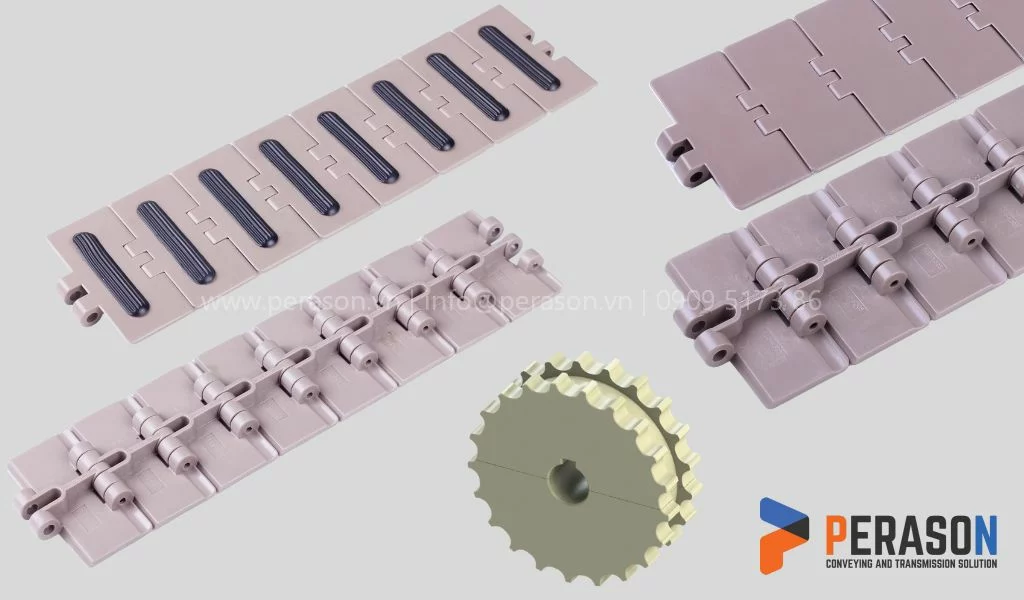

Flat Top Chain 820 Surface Variants and Mandatory Accessories

820 Plastic Chain Variants for various special applications:

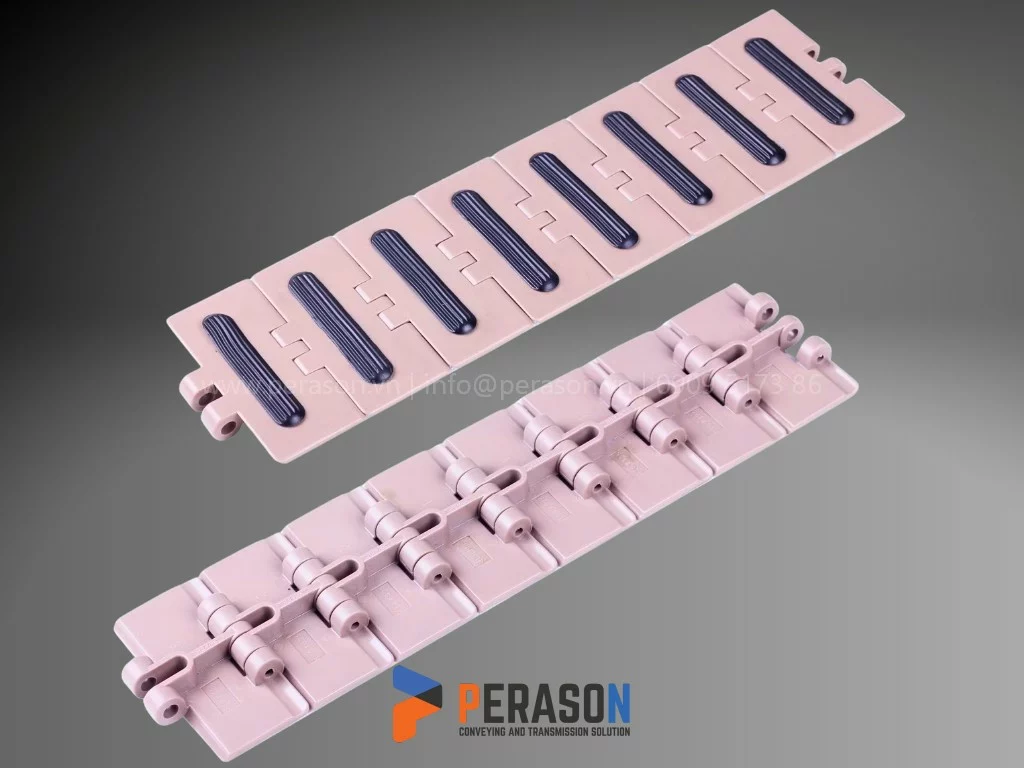

- Rubber Top Plastic Conveyor Chain: Chain plates are fitted with rubber friction inserts (NBR/EPDM/Elastomer). For Incline Applications, the rubber layer creates high grip, preventing products from sliding or rolling backward when conveying up/down slopes or carrying trays, boxes, and cartons.

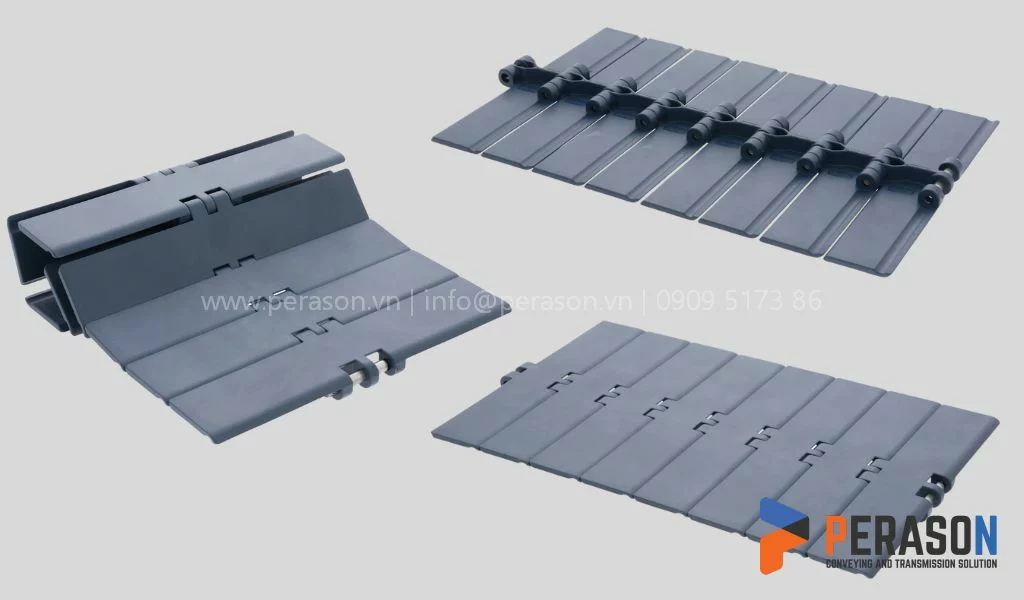

- Flighted Plastic Conveyor Chain: An 820 plastic chain type with flights (cleats) on the chain surface for automated packaging line applications. These flights form a small pocket that runs according to a PLC program step for products to be packed into boxes or PET bags.

Drive and Idler Sprockets are mandatory drive components, and the correct specifications must be chosen to synchronize with the 820 chain.

- Material: Nylon PA6 (Milling/Machining – White or Injection Molding – Black)

- Number of Teeth: Available sprockets: Z15, Z17, Z19, Z21, Z23, Z25

- Bore Diameter (Bore Dia.): Standard sizes: 20, 25, 30, 35, 40 (plain bore or bore with keyway and square shaft hole)

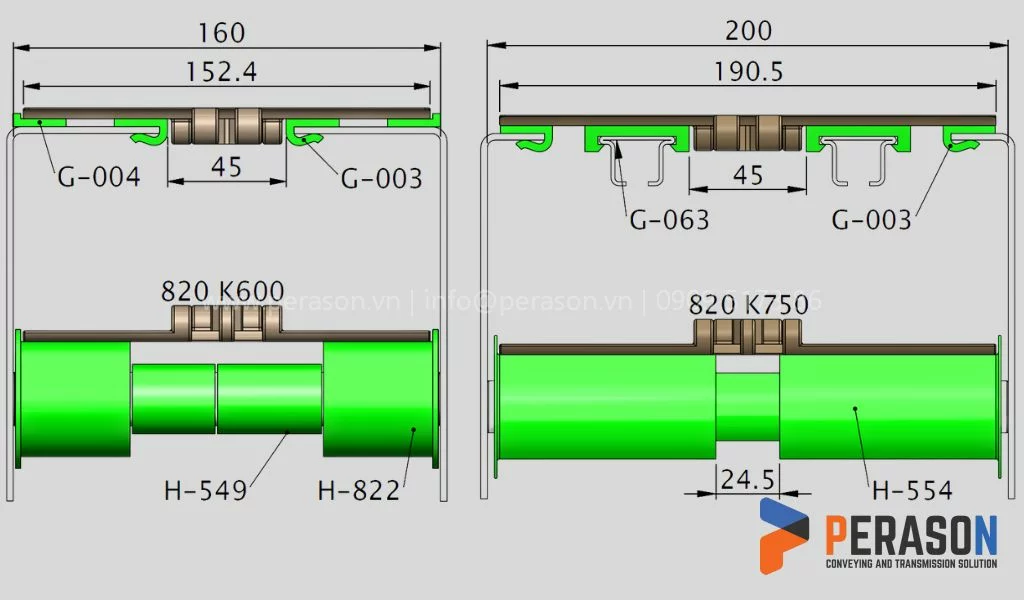

- Chain Wear Strips/Guides must be correctly selected.

Calculating 820 Plastic Conveyor Chain Load (Simple Formula): To estimate the actual load for the 820 plastic chain line, you can refer to the formula: [Length of 01 conveyor line (mm) / Bottle base diameter (mm)] x Weight of one unit of loaded product.

Inventory Policy and Customer Service

Perason always stocks the 820 plastic chain codes and many other types of conveyor chains and accessories in large quantities from various brands such as Hongsbelt, Uni, Habasit, Rexnord, Movexi, Plast Link, Forbo, ensuring:

- 100% Stock of common codes for Plastic Flat Top Chain.

- Same-day delivery with flexible payment methods.

- 18 months official warranty from the manufacturer.

- Replacement parts are always available for the 820 plastic chain series.

See more: 821 Heavy-duty plastic chain, stock available at competitive prices, same-day delivery.

See more: Introduction to Plastic Conveyor Chain – General Page.

Contact Us for Technical Consultation and Purchase of Flat Top Chain 820 Today

Don’t let old, worn-out, and noisy conveyor systems interrupt production and affect your factory’s output. Upgrade immediately to the 820 plastic chain series for the most continuous and stable performance. We have a team of specialized mechanical conveyor engineers, ready to provide in-depth technical consultation, design survey support, and product application advice completely free of charge.

Contact us today to receive a detailed quotation and consultation:

Technical / Sales Consultant (Ms. Hang): 0909.5173.86 – Perason Co.,Ltd